Iron spectrum analysis technology is one of the important technologies for equipment condition monitoring and predictive maintenance. This technology can accurately and reliably predict the wear status and potential faults of machine lubrication components, and promote maintenance actions to optimize equipment utilization and efficiency. The ferrographic analysis technology developed by Shuhao Instrument has established equipment diagnostic standards and is widely used in oil analysis laboratories worldwide. Ferrography is mainly used for image analysis of wear particles in lubricating oil. Ferrography technology utilizes the effect of a magnetic field to separate ferromagnetic wear particles and adherent particles from machine lubricating oil samples, and analyzes the morphology, size, quantity, and particle size distribution of their deposition and separation, in order to obtain relevant information about the wear process. Consistent with SHT0573-1993 Standard Test Method for Wear Particles of Lubricating Oil in Service (Analytical Ferrography). By using ferrography technology, the wear status of mechanical equipment during operation can be diagnosed and monitored, thereby improving the reliability and safety of the system. One of the important tools for applying ferrography technology is the ferrograph.

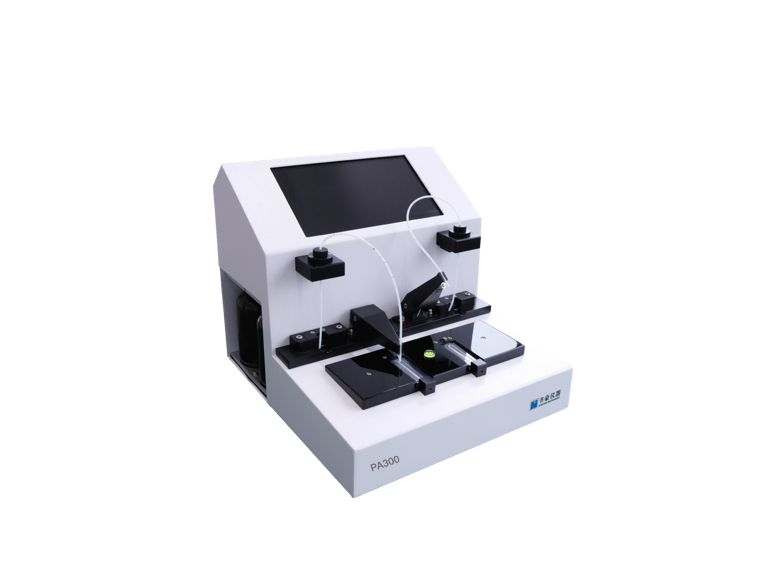

The PA300 dual analysis ferrograph is designed as two independent circuits, allowing for the preparation of two oil samples simultaneously. The operator can choose between automatic mode and semi-automatic mode to make the spectrum.

Application field:

Transportation Industry - Internal Combustion Locomotive Inspection

Steel Industry - Fan Testing

Electric Power Industry - Generator Set Testing

Naval Defense - Transmission Gearbox Inspection

Power supply: AC220V, 50Hz, equipped with a 12V power adapter;

Measurement range of abrasive particles: 0 μ M~800 μ M;

Sample injection method: Micro pump pneumatic, automatic injection;

Cleaning methods: automatic cleaning and manual cleaning;

Magnetic field: maximum magnetic flux density 1.8T (± 0.1T), maximum magnetic field gradient>0.5T/mm;

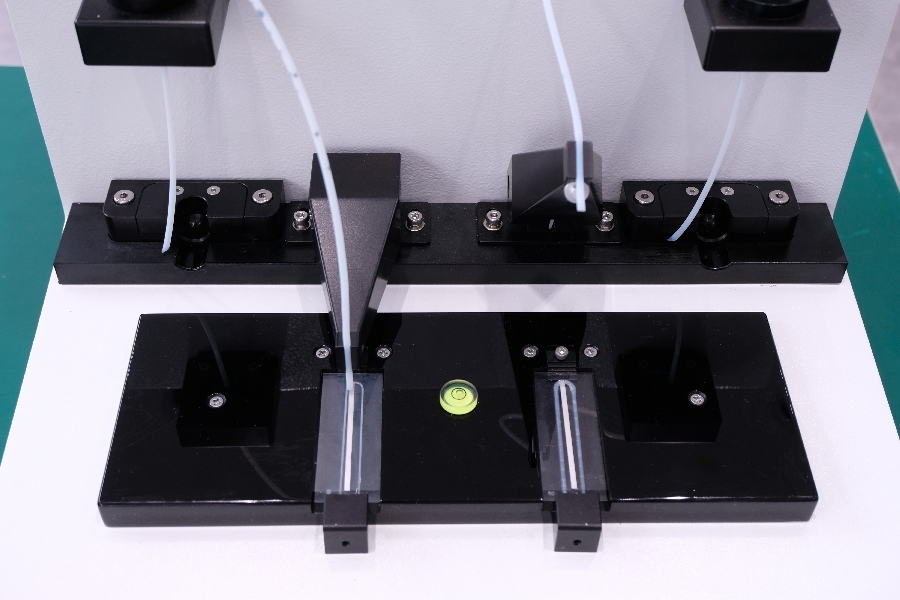

Permanent magnet, high gradient magnetic field, iron abrasive particles arranged neatly to avoid stacking phenomenon;

Using tetrachloroethylene as a dilution and cleaning solvent;

Spectral channel: dual channel synchronous spectrum generation;

Spectral inclination angle: 1 ° to 5 °;

Provide a standard abrasive grain atlas sample book;

Equip corresponding consumables and accessories such as ferrographs;

Display screen: equipped with a 10.1-inch LCD touch screen;

Oil sample transportation: adjustable flow rate range of 10-30ml/h;

The cleaning agent flow rate is adjustable, with a maximum flow rate greater than 100 ml/h;

Measurement resolution: 1 μ M;

Single analysis sample size: 1ml;

Oil pipeline size: outer diameter 2.6 millimeters, inner diameter 1.8 millimeters;

Iron spectrum substrate size: 60 × 24 × 0.17 mm;

Equipped with a built-in waste liquid collection device, the vacuum pump extracts the waste liquid into the waste liquid bottle, avoiding the volatilization of harmful organic vapors and protecting the health of operators;

Size: 395mm * 355mm * 335mm;

Weight: Approximately 14kg.

The moisture in the oil has almost no effect on the production of spectra;

Once the oil sample is ready and inserted, the instrument can automatically perform and the operator can perform other tasks;

Convenient button operation;

Adjustable control of sample flow rate to ensure consistent spectral deposition and repeatability;

Produce 2 spectra simultaneously in less than 20 minutes;

The spectrum is transparent, allowing for the differentiation of metal, organic, and non-metal particles, making it easier to diagnose;

The particles are arranged according to their magnetization coefficient and size, which facilitates rapid analysis of the particles;

Rarely does particle accumulation occur, making it easy to observe.