GB/T 11140 Standard Test Method for Sulfur in Petroleum Products Using Wavelength Dispersive XX-ray Fluorescence Spectroscopy;

NB/SH/T 0842 Determination of Sulfur Content in Gasoline and Diesel by Monochromatic Wavelength Dispersive XX-ray Fluorescence Spectroscopy;

ASTM D2622 Standard Test Method for Sulfur in Petroleum Products by Wavelength Dispersive XX-ray Fluorescence Spectroscopy;

ASTM D6334 Standard Test Method for Sulfur in Gasoline by Wavelength Dispersive XX-ray Fluorescence Spectroscopy;

ISO 20884 Petroleum Products-Determination of Sulfur Content in Automotive Fuels-Wavelength Dispersive XX-ray Fluorescence Spectroscopy;

ASTM D7536 Standard Test Method for Determination of Chlorine in Aromatic Hydrocarbons by Monochromatic Wavelength Dispersive X-ray Fluorescence Spectroscopy;

NB/SH/T 0977 Determination of Chlorine Content in Light Hydrocarbon Products by Single Wavelength Dispersive X-ray Fluorescence Spectroscopy;

ASTM D4929 Standard Test Method for Determination of Organic Chlorides in Crude Oil (Method C).

Monochromatic excitation energy dispersive X-ray fluorescence (abbreviated as MEDXRF) technology is a trace elemental analysis method optimized by introducing a mono-chromatized excitation source based on traditional energy dispersive X-ray fluorescence (EDXRF) technology. Its primary advantages include reducing background interference and improving detection sensitivity, with broad applications in quantitative trace and ultra-trace elemental analysis in environmental monitoring, food safety, and materials science.

Application Sectors:

Rapid analysis of sulfur, chlorine, silicon, and phosphorus in oil products such as gasoline and diesel

Rapid detection of phosphorus content in edible oils

Rapid detection of aluminum content in food additives

Analysis of aluminum, phosphorus, and potassium in food, as well as light elements in industrial applications

Ultra-low Detection Limit (300 s):

Si: 1.5ppm ,P: 0. 3ppm ,S: 0.3ppm ,Cl: 0.2ppm

Instrument Performance Parameters:

Measurement Method | MEDX Monochromatic Energy Dispersive Analysis |

Analytes | Gasoline、Diesel 、Jet Fuel、Kerosene、 Other Distillate Fuels、 Naphtha、Residual oil、Lubricating base oil、Hydraulic oil、Crude oil、Automotive gasoline、Alcohol-containing gasoline and biodiesel |

Element range | Si,S,Cl |

Test concentration range | S、Cl:0.5ppm-10wt% Si:1.5ppm-10wt% |

Detection limit |

S≤0.15ppm;Cl≤0.1ppm;Si≤0.5ppm; |

Measurement time | 300S |

Repeatability | S: RSD ≤ 5% for seven repeated tests above 5 ppm; RSD ≤ 10% for 2–5 ppm; range ≤ 0.5 ppm below 2 ppm.

Cl: RSD ≤ 5% for seven repeated tests above 5 ppm; RSD ≤ 10% for 2–5 ppm; range ≤ 0.5 ppm below 2 ppm.

Si: RSD ≤ 5% for seven repeated tests above 10 ppm; RSD ≤ 10% for 6–10 ppm; range ≤ 1.5 ppm below 6 ppm. |

Reproducibility | S and Cl below 2 ppm with a deviation ≤1 ppm; Si below 5 ppm with a deviation ≤2 ppm |

Operating Environment | Temperature 5℃–35℃, Humidity 20%–85% |

Power Supply | AC/DC power adapter input: 100–240 VAC, 50/60 Hz |

Leak-proof design:

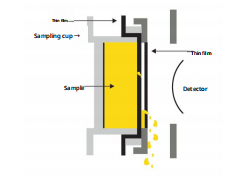

“Side irradiation”to minimize the impact of accidental sample contamination on the detection window

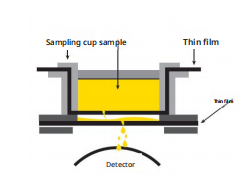

Conventional EDXRF instruments feature a thin film covering the sample chamber window to prevent accidental sample leak- age into the detector and X -ray tube. If this film ruptures, the sample may infiltrate the detector and X -ray tube, causing substan- tial maintenance costs.

The SH-MEDX3600 inserts the sample vertically from the side into the instrument. This innovative design ensures that any samples with acci- dental leakage do not contact the instrument’s valuable components, facilitating cleaning and maintenance while preventing significant damage.

Traditional instrument sample chamber

Side-illumination analyzer sample chamber

Repeatability:

Number of tests | Calibration curve | Elemental content | |||

P(PPM) | Si(PPM) | S(PPM) | Cl(PPM) | ||

1 | Low-oil | 5.09 | 10.16 | 5.18 | 5.07 |

2 | Low-oil | 5.20 | 9.90 | 4.88 | 5.17 |

3 | Low-oil | 4.96 | 9.65 | 4.93 | 5.15 |

4 | Low-oil | 5.35 | 10.28 | 4.91 | 4.90 |

5 | Low-oil | 4.85 | 10.32 | 5.08 | 5.15 |

6 | Low-oil | 5.05 | 10.45 | 4.93 | 4.92 |

7 | Low-oil | 4.86 | 10.15 | 4.86 | 4.87 |

8 | Low-oil | 5.13 | 9.93 | 5.26 | 4.94 |

9 | Low-oil | 5.13 | 10.31 | 5.24 | 5.14 |

10 | Low-oil | 4.96 | 9.48 | 5.11 | 5.39 |

11 | Low-oil | 5.17 | 9.88 | 5.03 | 5.23 |

Average content (ppm) | 5.07 | 10.05 | 5.04 | 5.08 | |

Measured standard deviation SD | 0.14 | 0.29 | 0.14 | 0.15 | |

3s value | 0.43 | 0.87 | 0.42 | 0.46 | |

Relative standard deviation RSD(%) | 2.85% | 2.89% | 2.76% | 0.03 | |