The iron wear tester is mainly used to detect metal particles in oil samples extracted from cylinder friction oil. PF100 provides a simple and easy-to-use platform.

Analysis method:

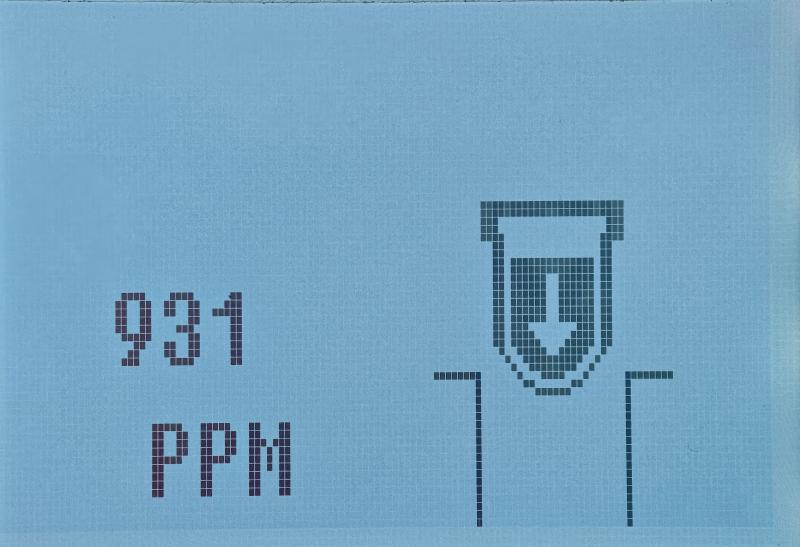

Place a 5ml test tube with a sample directly into the hole of the instrument, and its metal content (PPM) will be displayed on the screen in less than 2 seconds. Collaborating with a cold corrosion testing kit to obtain a ship cylinder oil total iron measurement iron wear instrument

Application field:

Machine system wear monitoring

Evaluation of lubricating oil for machine systems

Evaluation of ferromagnetic debris in gearbox

Residual assessment of bearing oil lamps

Technical parameters:

Measurement range ppm: 0-2500ppm;

Sample detection method: ferromagnetic method;

Working temperature range: 5 ℃ -40 ℃;

Display resolution: 5ppm;

Repeatability: +/-10ppm (0-1000ppm),+/-20ppm (>1001 PPM);

Sample bottle: Standard 5ml test tube;

Weight: 1.1kg;

Test time: <3 seconds per sample;

Power supply: 24V DC - Power supply includes UK, EU, and US power adapters;

Size: 220mm * 220mm * 75mm.

Iron wear tester is mainly used to detect metal particles in oil samples extracted from cylinder friction oil;

PF100 provides a simple and easy-to-use platform;

This instrument is independently developed by Soohow Instrument and has undergone internal quality management control. It is an instrument with high accuracy and reliability;

This instrument is an ideal site for testing and analyzing oil samples, such as on ships or in remote locations where complete laboratory analysis cannot be performed;

PF100 is a precision magnetometer suitable for field applications.