(1) Can quickly measure the content of all ferromagnetic wear particles in oil, and provide quick quantitative analysis for ferromagnetic particles in oil.

(2) By utilizing equipment to detect changes in wear intensity at an early stage of wear, and adjusting the sampling monitoring time density, trend analysis can be conducted on the instrument and equipment to further inspect and replace the problem, avoiding serious losses.

The DR100 Direct Reading Ferrograph is a high-efficiency, professional oil analysis equipment, specifically designed for the evaluation of machine system lubricating oil, ferromagnetic debris in gearboxes, oil residue in bearings, etc. It is also used to monitor the wear status of machine systems.

APPLICATION FIELD:

Machine system wear monitoring

Lubricating oil evaluation of machine systems

Gear box ferromagnetic abrasive evaluation

Residual assessment of bearing oil lamp

TECHNICAL INDICATORS:

. Single sampling volume 1ml;

. Single analysis time: less than 10 minutes;

. USB interface:4;

. Internet connection:RJ45;

. Operating system:windows7;

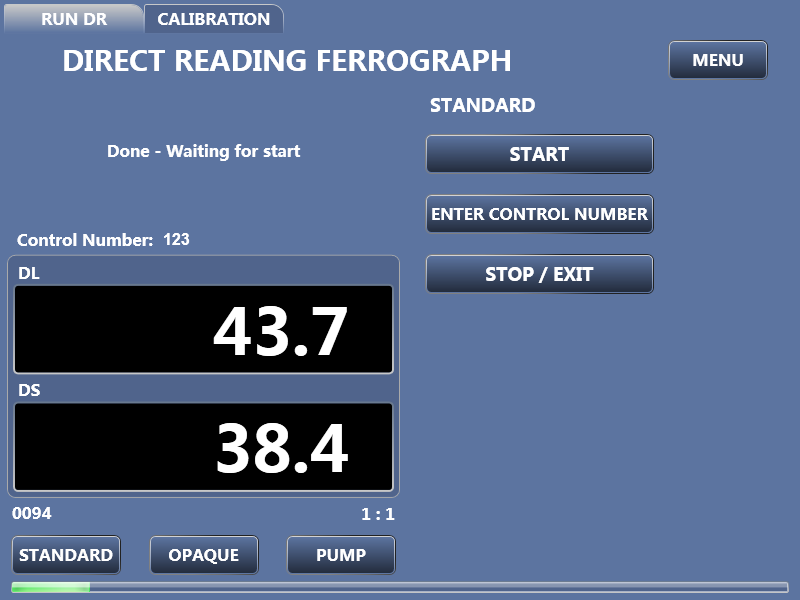

. Display:high sensitivity touch screen;

. Cleaning agentl:tetrachloroethylene;

. Magnetic field:the maximum magnetic field gradient >5.0T/cm,the maximum magnetic flux density >1.5T;

. Test resolution:0.1 (one decimal place);

. Injection method:automatic injection;

. Power supply voltage:220VAC±10%,50Hz (the instrument uses a 12VDC 5A power adapter).

PERFORMANCE CHARACTERISTICS:

. The instrument is equipped with a 7-inch touch display;

. Internal self-diagnosis of the microprocessor to achieve reliable functions;

. Support USB and network port connection;

. It can quickly measure the content of all ferromagnetic wear particles in the oil,and can quickly and quantitatively analyze the ferromagnetic particles in the oil;

. Can use the equipment to detect the change of wear intensity in the early wear,and by adjusting the sampling monitoring time density,through trend analysis on the equipment,further check and replace the problem to avoid serious losses;

. New high-performance,low-power core,better anti-electromagnetic interference capability;

. The instrument positioning device can adjust the distance from the oil pipeline to the sensor,so that the state of the oil sample entrance is consistent,and the measurement accuracy is improved;

. Easy to carry,can work in outdoor environment;

. Application:To separate and evaluate wear particles and pollutant particles in lubricating oil,hydraulic oil, coolant or fuel;

. Content:Quantitative measurement of the concentration of wear particles in the oil and provides basic wear trend data to help determine equipment status in a matter of minutes.