1. Calibration, testing methods, and accuracy meet the requirements of ISO 4402, GB/T 18854, and ISO 11171;

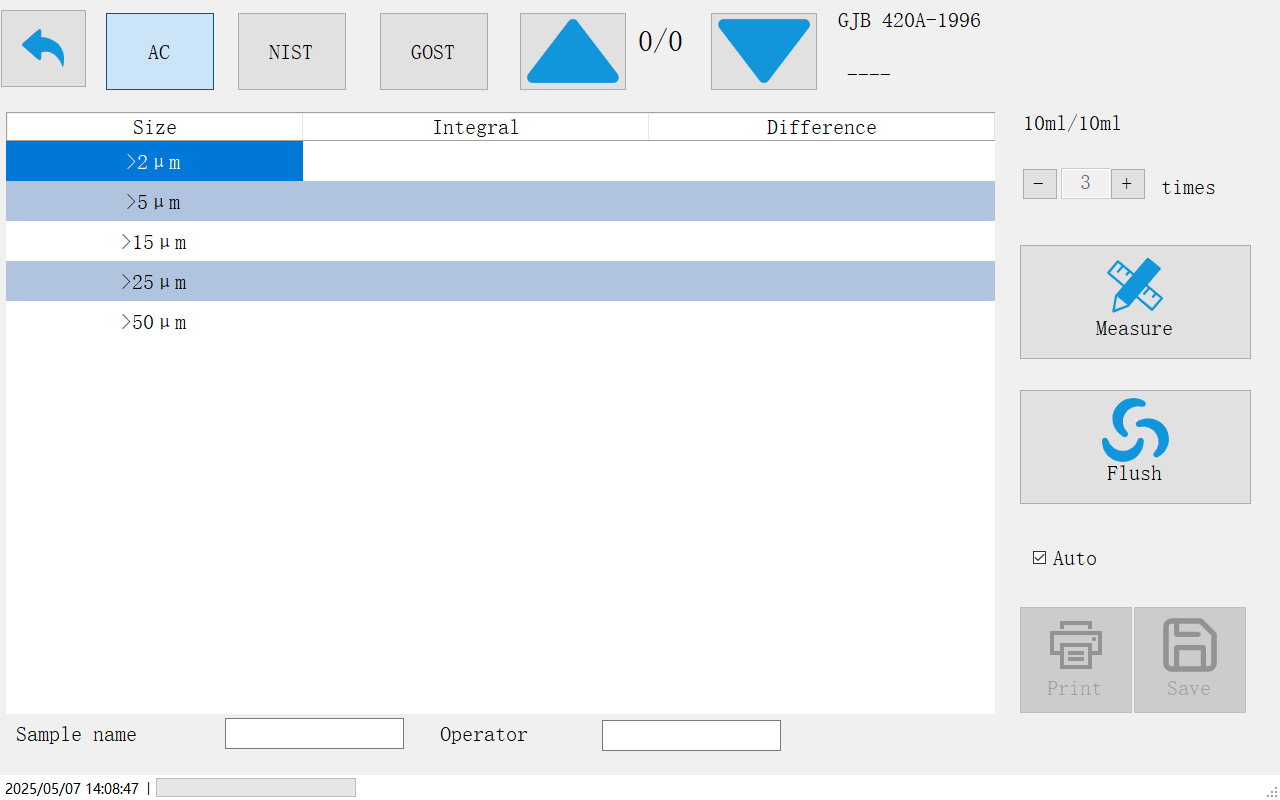

2. The built-in particle pollution level standards are as follows, and the required standards can be added according to user needs: NAS1638, ISO4406-1999, ISO4406-2007, ISO4406-1987, GB/T 14039-2002, GJB420B-2006, GJB420B-2015, GJB420A-1996, AS4059E, AS4059F, ROCT17216-1971, ROCT17216-2001, JTS-005, SAE749D-1963, AETF1A, NAS1638/ISO4406, etc.

The principle of light blocking method (light blocking method) is used to detect the size and quantity of solid particles in liquids, and to detect the pollution level of solid particles in hydraulic oil, lubricating oil, shale oil, transformer oil (insulation oil), turbine oil (turbine oil), gear oil, engine oil, aviation kerosene, water-based hydraulic oil and other oils; Detecting insoluble particles in organic liquids and polymer solutions.

Application field:

Military industry

Aerospace industry

Electricity industry

Transportation industry

Parameter

1. Light source: semiconductor laser;

2. Detection range: 0.8 μ m to 500 μ m;

3. Particle size range: 1-100 μ m (ISO4402) or 4-70 μ m (c) (GB/T18854, ISO11171);

4. Sensitivity: 1 μ m (ISO4402) or 4 μ m (c) (GB/T18854, ISO11171);

5. Detection channels: 32, with particle size adjustable at intervals of 0.01 μ m;

6. Sampling volume: 0.3-100ml, with an interval of 0.1ml;

7. Relative error of sampling volume: better than ± 0.5%;

8. Detection speed: 5-60mL/min (default 15mL/min);

9. Cleaning speed: 5-60mL/min (default 15mL/min);

10. Resolution: better than 10%;

11. Overlap error limit: 12000~40000 particles/mL;

12. Particle count repeatability: RSD<2%;

13. Detection accuracy: ± 41/2 grade (ISO 4406 standard);

14. Relative error of particle counting: ± 5%;

15. Maximum positive pressure of sample chamber: 0.8MPa, maximum vacuum: -0.08MPa;

16. Sample viscosity range:<650 cSt;

17. Sample temperature for testing: 0 ℃ to 80 ℃;

18. Working temperature: -20 ℃~60 ℃ Storage temperature: -30 ℃~80 ℃;

19. Power supply: 220V ± 10%, 50Hz; 180W;

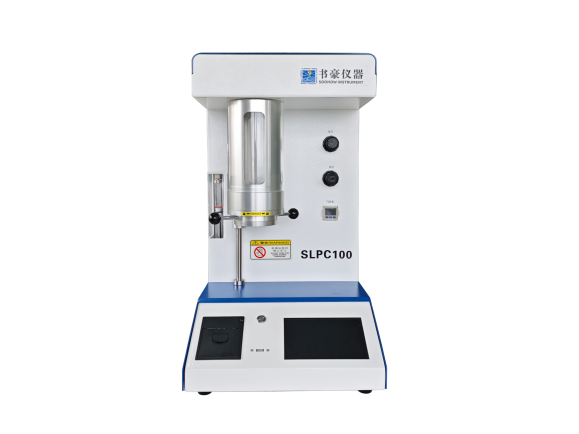

20. Host size: 355 × 400 × 620mm;

21. Weight of the host: 19kg.

Instrument features

1. Principle of photoresist method (shading method);

2. Calibration, testing methods, and accuracy meet the requirements of ISO 4402, GB/T 18854, and ISO 11171;

3. The built-in particle pollution level standards are as follows, and the required standards can be added according to user needs: NAS1638,SAE4059FI,SO4406-1999, ISO4406-2007, ISO4406-1987, GB/T 14039-2002, GJB420B-2006, GJB420B-2015, GJB420A-1996, AS4059E, AS4059F, ROCT17216-1971, ROCT17216-2001, JTS-005, SAE749D-1963, AETF1A, NAS1638/ISO4406, etc;

4. Configure high-performance large-sized particle counting sensors;

5. The industrial computer Windows system supports instrument control and calculation;

6. Optional configuration calibration curves: ACFTD, ISOMTD, latex ball, GOST and other calibration curves;

7. The test result storage includes embedded printer printing, software database storage, and USB storage functions.