The Wear Particle Image Acquisition and Intelligent Analysis System can efficiently adapt to the dual-analysis ferrograph, dual-rotary ferrograph, and Jiguang-tube ferrograph developed by our company, achieving full-process collaborative operation.

The Wear Particle Image Acquisition and Intelligent Analysis Software is a professional wear particle image acquisition and analysis software system independently designed and developed by the Testing Technology Team of Soohow Instruments, featuring a concise interface and simple operation. The software includes three major functions: wear particle image acquisition, wear particle recognition, and wear analysis, with image acquisition adopting high-quality microscope cameras for clear imaging and high color reduction; the wear particle recognition model is trained by deep learning technology based on tens of thousands of wear particle image samples from industrial field lubricating oil, with high accuracy and strong generalization ability; the wear analysis is designed based on the SH/T 0573 "Test Method for Wear Particles in Used Lubricating Oils (Analytical Ferrography)" detection standard, which is highly matched with the actual application scenarios. The independent design and development ensure that the software has extremely high expandability, can be personalized according to customer needs, and is deeply integrated with the customer's laboratory information ecosystem.

S/N | Name | Specifications | Remarks |

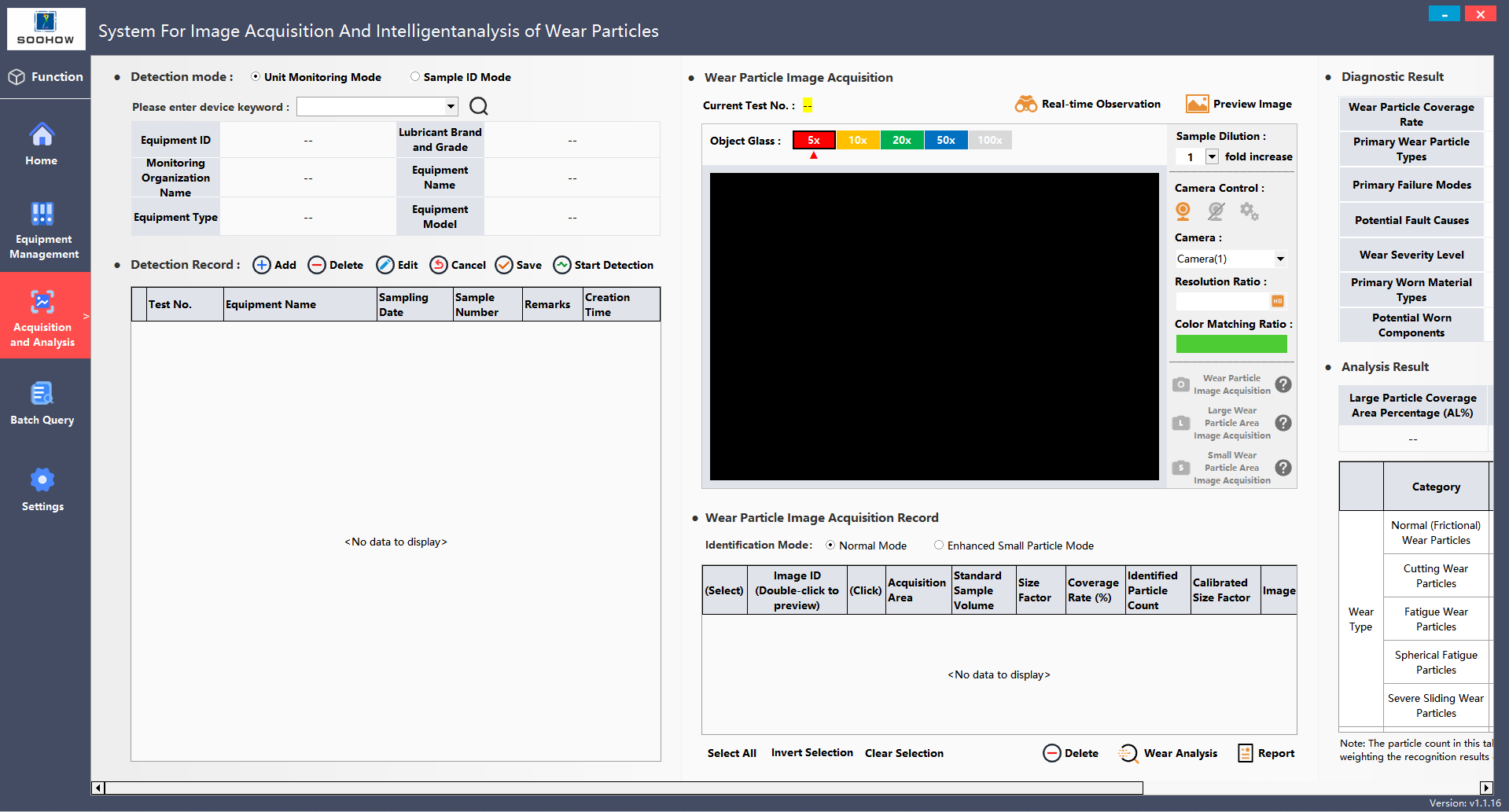

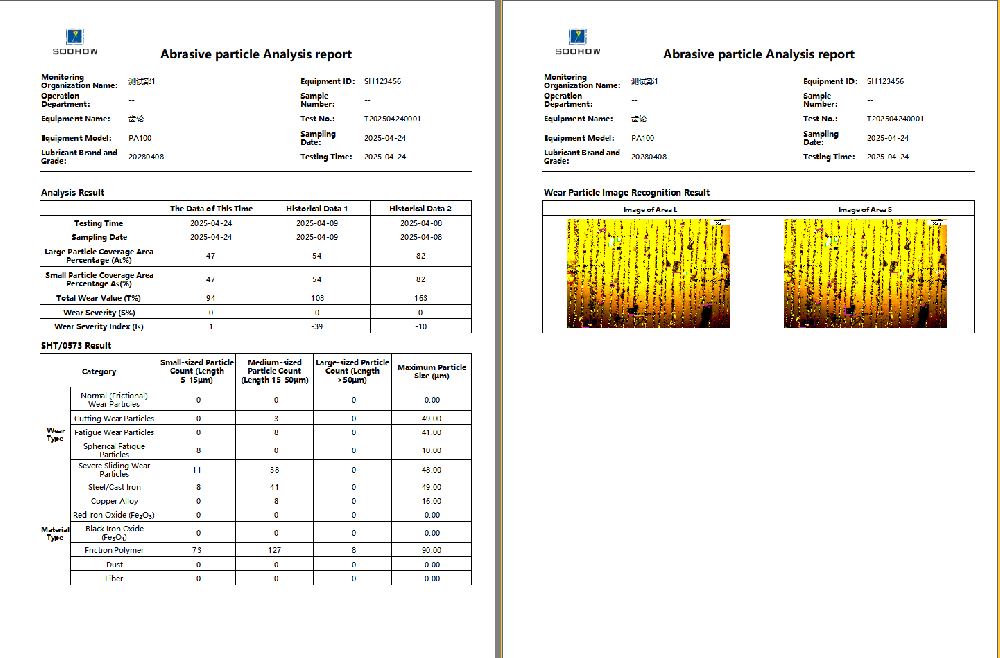

1 | Design Standard | SH/T 0573 "Test Method for Wear Particles in Used Lubricating Oils (Analytical Ferrography)" | |

2 | Computer Configuration | 10th Gen Intel Core i5-10500, 8GB RAM | Equivalent or higher configuration |

3 | Camera | E3ISPM2000KPA | Compatible with other models |

4 | Transmission Line | E301195 UL AWM style 2725 | Compatible with other models |

5 | System Software | Wear Particle Image Acquisition and Intelligent Analysis System | |

6 | Microscope Calibration Ruler | 1DIV =0.01mm | |

7 | Wear Particle Recognition Range | 0~1200um | |

8 | Acquisition Type | Real-time Acquisition | |

9 | Image Resolution | 5480*3648 / 2736*1824 | |

10 | Wear Particle Recognition Categories | 12 Types | (Normal wear particles, fatigue wear particles, cutting wear particles, severe sliding wear particles, spherical wear particles, copper wear particles, oxide wear particles, etc.) |

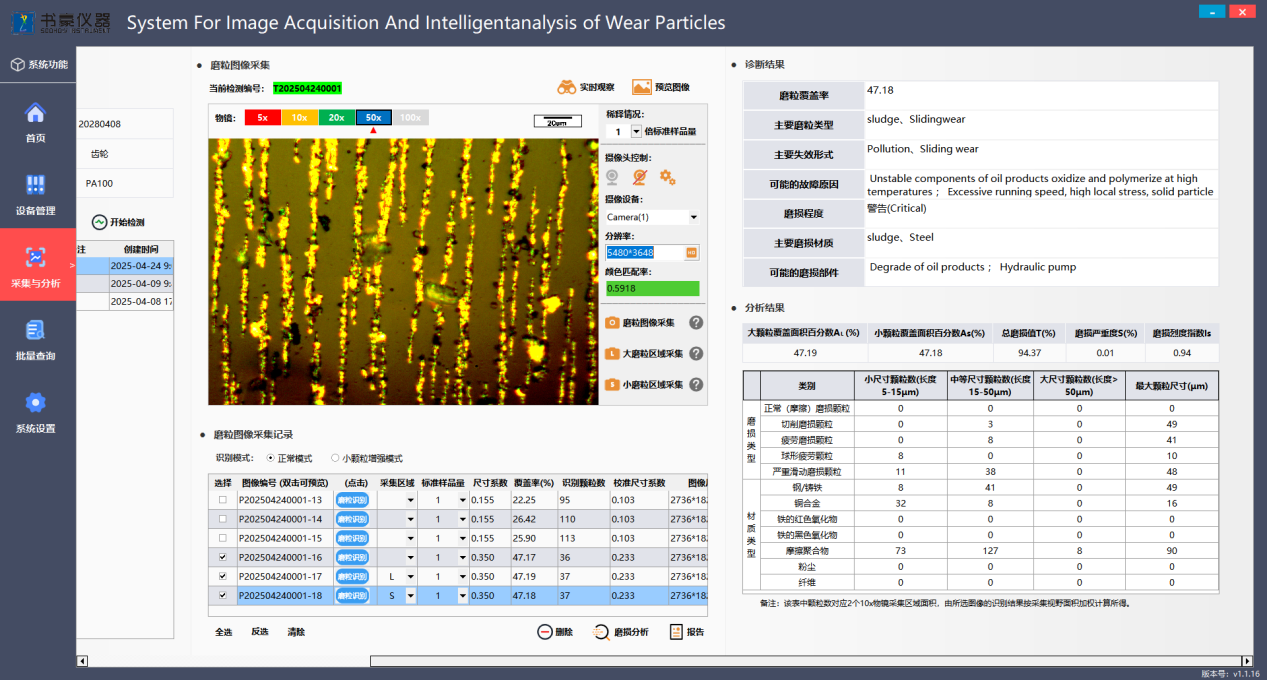

1. High-speed microscope camera selected

2. Image acquisition system

3. Wear particle intelligent recognition system

4. Reporting function

5. Convenient data interaction

6. Support for highly personalized design