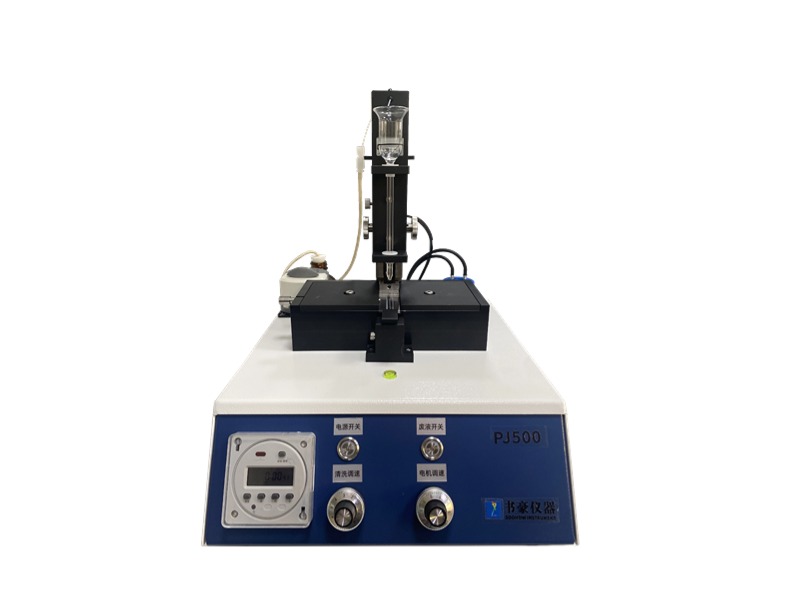

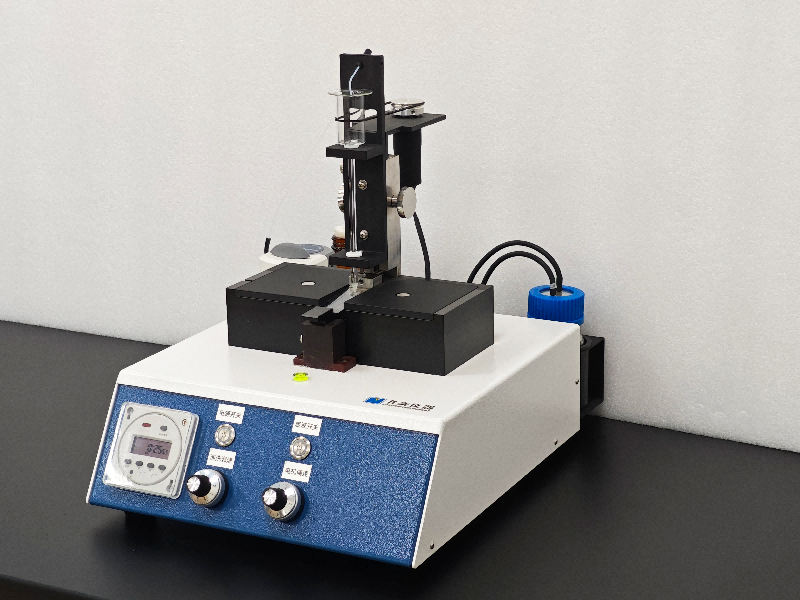

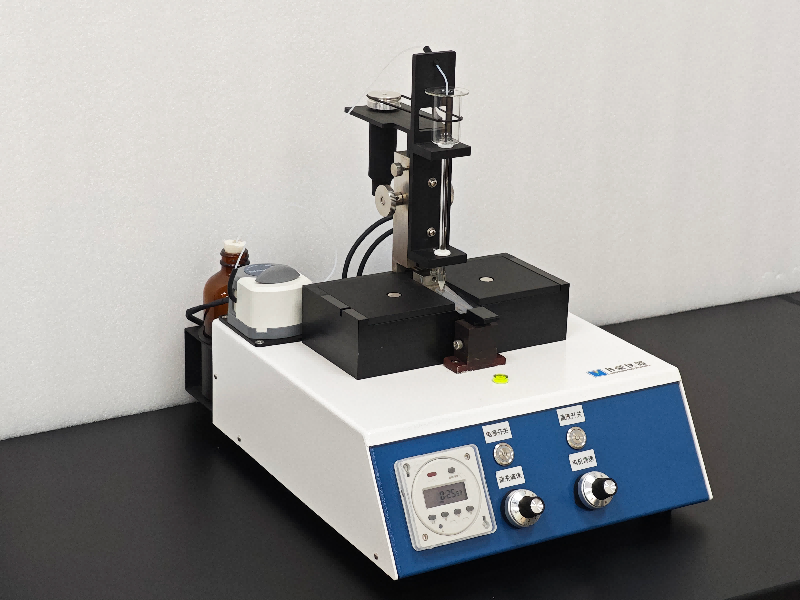

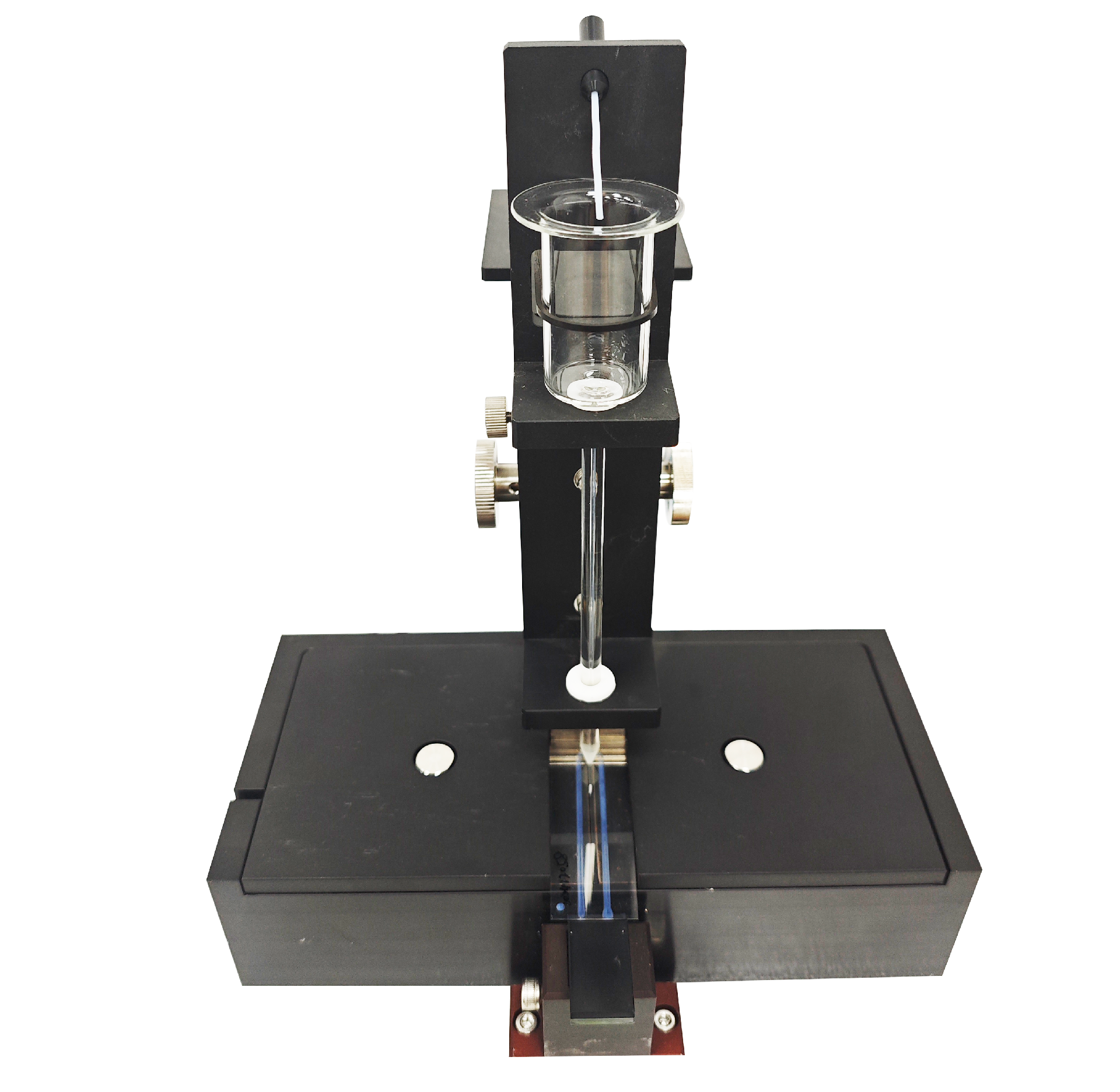

PJ500 is a complete ferrographic analysis system used to separate and evaluate wear particles and pollutant particles in lubricating oil, hydraulic oil, coolant or fuel in use. It consists of a tube type ferrograph, microscope, industrial camera, heating plate (optional), and image acquisition software. In order to ensure the quality of the spectrum production, the diluted oil is directly passed through a thistle shaped tube under its own gravity and flows uniformly through the ferrogram. The ferromagnetic particles in the oil are deposited onto the spectrum under the action of a magnetic field, effectively avoiding damage, deformation, and other injuries caused by external forces during the spectrum production process; Thoroughly rinse the spectrum by controlling the flow rate and flow rate of the cleaning agent; Analyze the spectrum after drying. Place the prepared spectrum smoothly on the sample stage of the microscope, and conduct in-depth analysis of the worn particles by using analysis methods such as transmission light, reflection light, polarized light, red green light source, and spectrum heating of the microscope, referring to the standard abrasive grain pattern.

Application field:

Railway system - ferrograph used for diesel locomotive inspection

Steel Industry - Fan Testing

Electric Power Industry - Generator Set Testing

Naval Defense - Transmission Gearbox Inspection

Technical indicators

(1) Iron spectrum analyzer particle inspection range: 0-800 μ M;

(2) Sample injection method: manual injection, the sample is injected into a thistle tube capillary tube and drips under gravity. The tested oil sample drips through its own gravity without passing through a peristaltic pump, avoiding the destructive effect of the peristaltic pump on the abrasive particles. The spectrum preparation process will not cause deformation of the abrasive particles;

(3) Injection flow rate: 0.4ml/min;

(4) Single analysis of oil sample: 2-3ml;

(5) Magnetic field: maximum magnetic flux density ≈ 1.8T, maximum magnetic field gradient>0.5T/cm;

(6) Magnetic field separation: optimized permanent magnet design, high gradient magnetic field, ensuring neat arrangement of iron abrasive particles and avoiding stacking phenomenon;

(7) Cleaning method: Automatic cleaning, can be timed;

(8) Cleaning speed regulation: adjustable;

(9) Spectrum size: 60 × 24 × 0.17mm;

(10) Display screen size: 3.5 "TFT;

(11) Dimensions: length, width, height 340mm x 300mm x 430mm;

(12) Weight: 9.6Kg,

(13) Working temperature: 18-35 ℃;

(14) Power supply voltage VAC220 ± 10%, 50Hz.

(1) Efficient separation of abrasive particles and pollutant particles in oil samples;

(2) The spectrum making process will not cause abrasive deformation;

(3) High magnetic field gradient ensures neat arrangement of iron abrasive particles and avoids accumulation phenomenon;

(4) Provide a reference graph library to accurately determine the location and cause of wear faults;

(5) Less solvent required, no need for external compressed gas;

(6) The design concept of volatilizing cleaning agents into the air ensures the health of personnel;

(7) One click rotating design, quick replacement of glass thistle tube, easy to maintain, clean, and maintain;

(8) The streamlined appearance design and exquisite combination structure make the overall design simple and elegant;

(9) New high-performance, low-power core with stronger resistance to electromagnetic interference;

(10) The speed of spectrum making can be adjusted, which can effectively improve the success rate of spectrum making;

(11) The instrument positioning device can adjust the distance between the oil pipeline and the ferrogram substrate to maintain a consistent state at the inlet of the oil sample, improving the reproducibility of ferrogram production;

(12) Convenient to carry and work in outdoor environments;

(13) The ferrographic analysis method has a wide range of size inspection and can obtain various information about the abrasive particles;

(14) Application scope: Used to separate and evaluate wear particles and pollutant particles in lubricating oil, hydraulic oil, coolant or fuel in use;

(15) Testing content: concentration and size of abrasive particles; Morphology of abrasive particles (causes and mechanisms of abrasive particle formation); Composition of abrasive particles (the location where abrasive particles are produced).