The RF500 dual rotary ferrograph is a new type of equipment operating condition oil analysis instrument, which meets the requirements of NB/T 51068-2017 "Iron spectrum analysis method for gear oil in coal mine oil equipment (rotary ferrograph method)" and Q-SH.J 014-2010 "Technical standard for iron spectrum analysis of coal mine equipment oil".

The RF500 dual rotary ferrograph is a new type of equipment operating condition oil analysis instrument, which meets the requirements of NB/T 51068-2017 "Iron spectrum analysis method for gear oil in coal mine oil equipment (rotary ferrograph method)" and Q-SH.J 014-2010 "Technical standard for iron spectrum analysis of coal mine equipment oil". It uses a high field gradient magnetic field to deposit ferromagnetic and paramagnetic particles generated by wear in equipment lubricating oil (or other liquid media) on a glass substrate (spectrum), and arranges them into a ferromagnetic line map according to the magnetic field force distribution. The dual rotating ferrograph adopts a dual magnetic head design, which greatly improves the spectral efficiency and tolerance to various contaminated oil samples. It is particularly suitable for qualitative and quantitative ferrographic analysis of severely contaminated oil. Then, using a ferrographic microscope, the physical characteristics such as size, shape, size, color, and surface texture of the abrasive particles can be observed, and the number of abrasive particles can be counted to identify the wear type and obtain the wear status of the equipment.

Application Fields

The RF500 dual rotating iron spectrometer can be used for:

1. Analyze the operating conditions of diagnostic equipment and predict mechanical equipment failures caused by wear and tear;

2. Assess the performance of lubricating oil and determine whether its use is normal;

3. Develop running in specifications for new machines to improve the reliability and performance of equipment operation;

4. Collect the root cause parameters of hidden faults in equipment operation for the study of friction and wear mechanisms;

5. To achieve the goal of reducing equipment failure rates and extending equipment lifespan

1. The magnetic field gradient distribution in the abrasive deposition zone is 100-1000 Gs, and the highest magnetic induction intensity at the working point is ≥ 600 Gs;

2. Large area of magnetic head particle deposition area, inner diameter of magnetic head inner ring 11.5 ± 0.5mm, width 0.5 ± 0.2mm; The inner diameter of the magnetic head coil is 19.0 ± 0.5mm, and the width is 0.5 ± 0.2mm; Inner diameter of magnetic head outer ring (29.0 ± 0.5mm, width 0.5 ± 0.2mm);

3. The magnetic head has three working speeds, with a default speed of 75rpm/min for the spectrum setting, 150rpm/min for the cleaning setting, and 200rpm/min for the spin drying setting. Each speed can be adjusted within a certain range;

4. Measurement range: 0 μ m to 3000 μ m;

5. The radial runout of the magnetic head during operation is less than ± 100 μ m, and the total runout of the end face is less than ± 100 μ m;

6. Spectral glass substrate size: 55 * 55 * 0.17 (mm);

7. The abrasive particles are uniformly deposited along the deposition ring with equal probability on the spectral plane, and there is basically no overlap phenomenon. The effective sample area deposited with equal probability is ≥ 47mm2, and the sample area deposited with equal probability in the inner ring is ≥ 9mm2;

8. Reproducibility error: The mean error of qualitative iron spectra in 8 microscope fields is less than 10%, and the mean error of quantitative iron spectra in 4 microscope fields is less than 15%;

9. Size: 700mm * 280mm * 240mm;

10. Weight: Approximately 14kg;

11. Power supply: 220 ± 10% VAC, 50Hz, equipped with 24V 6A power adapter;

12. Power consumption:< 150W.

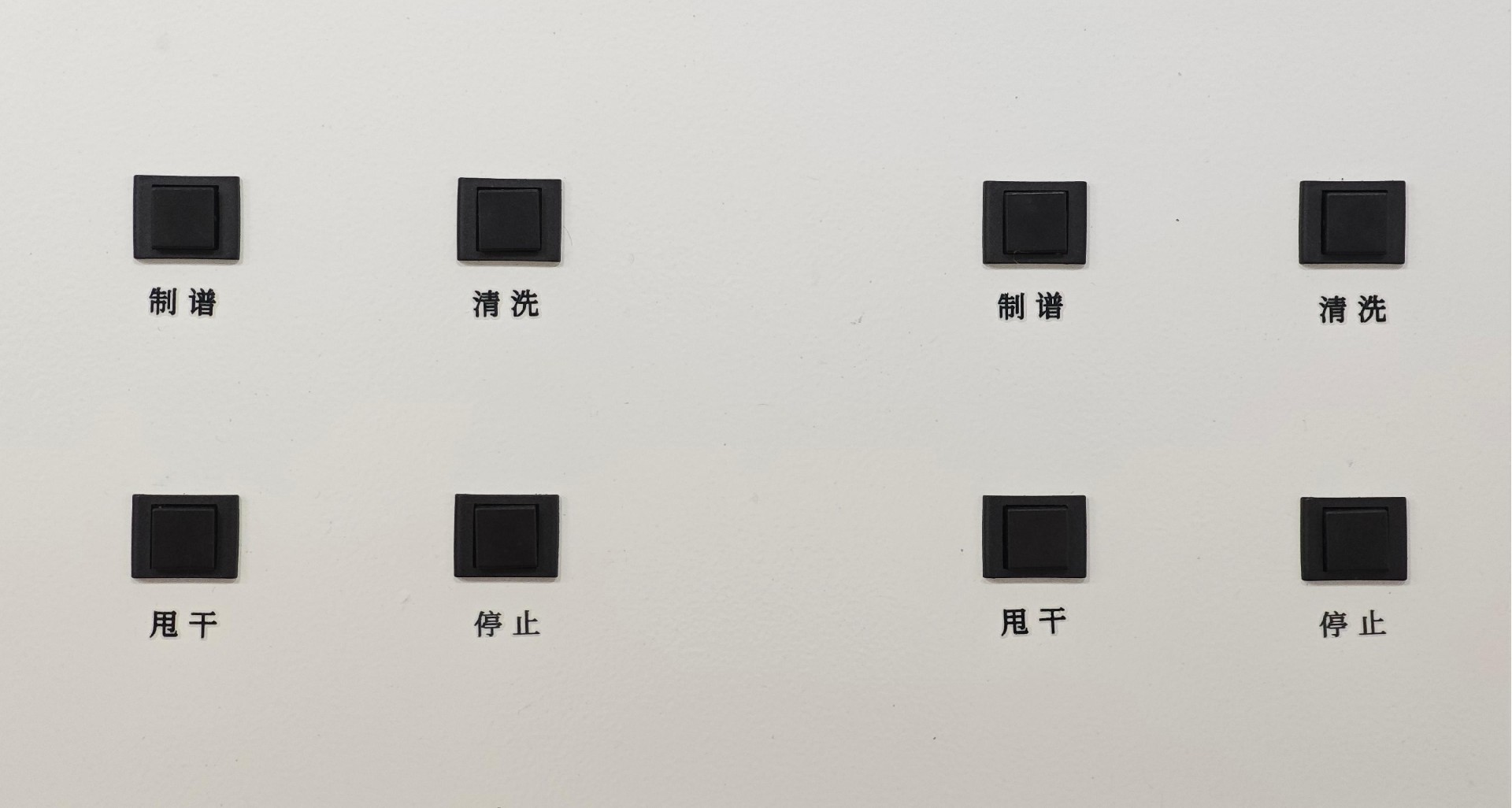

1. Equipped with both physical buttons and a 10.1-inch LCD touch screen;

2. Spectral channel: Dual channel synchronous spectral production, independent of each other;

3. Equipped with automatic installation and fixing devices for spectra;

4. Dual stepper motor control signal output, the motor works vertically and is controlled separately without interference;

5. Equipped with a timing function, each state will stop when the time is up;

6. Dual magnetic head design, doubling the spectral efficiency; Strong magnetic head design, high abrasive deposition efficiency, equipped with inner, middle, and outer concentric magnetic rings, capable of depositing abrasive particles of different sizes: large, medium, and small;

7. The magnetic head speed and operating time can be adjusted to suit different viscosities and contaminated oil samples;

8. The sedimentation area of abrasive particles is large, and there is a large amount of information samples available for analysis;

9. The cleaning has automatic injection function and device, and the cleaning speed can be adjusted;

10. Spectrum making, cleaning, and spin drying have timing functions, and the speed and cleaning time of the cleaning solution can be adjusted;

11. Active pumping waste liquid recovery reduces the risk of pipeline blockage and improves recovery efficiency;

12. The instrument has power outage protection and memory function, and can continue to complete oil sample spectroscopy when powered on again;

13. Configure a high-resolution dual path optical microscope, a 16 megapixel imaging system, and a desktop computer.