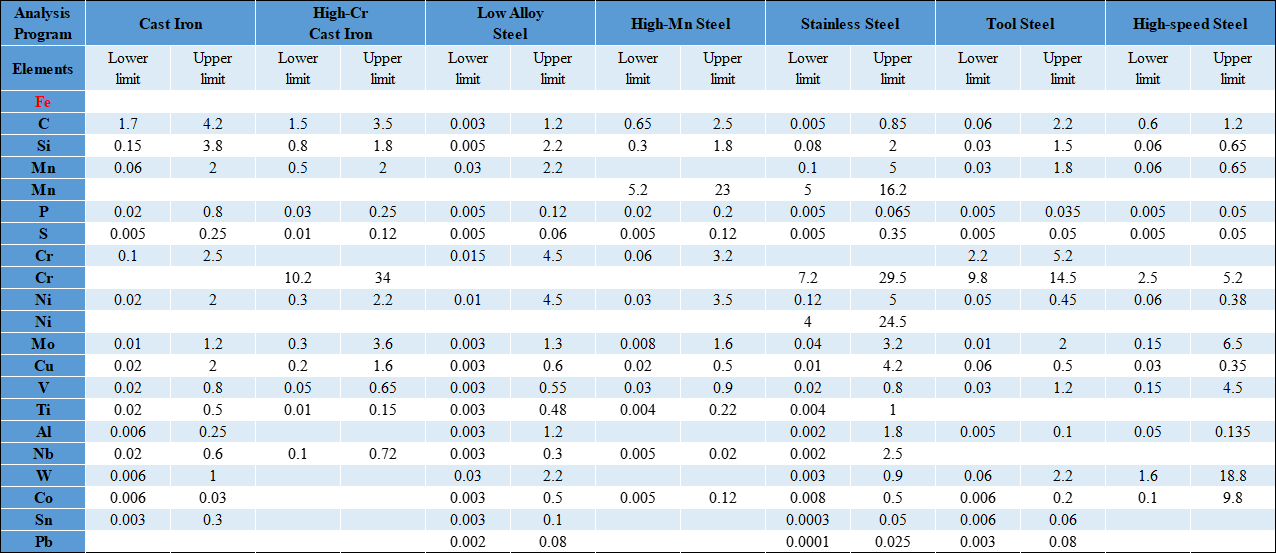

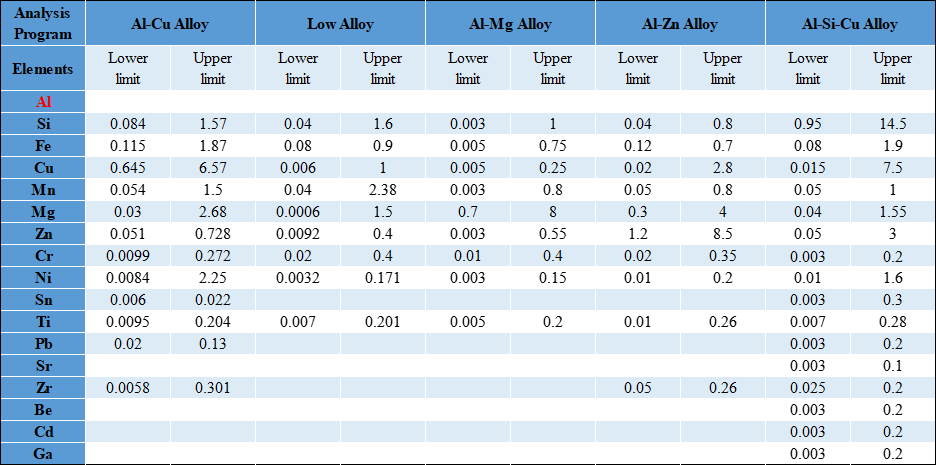

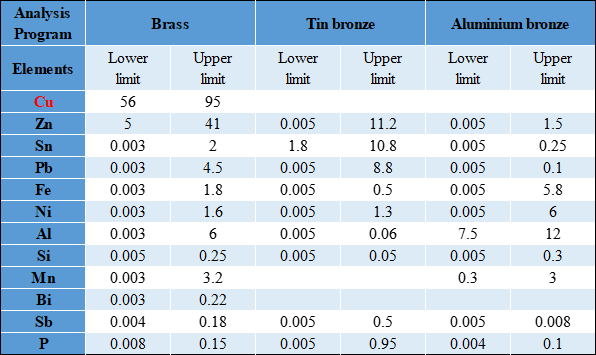

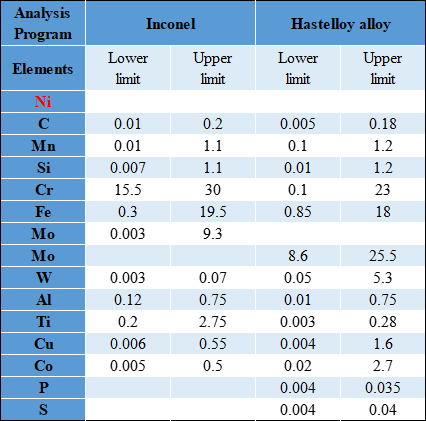

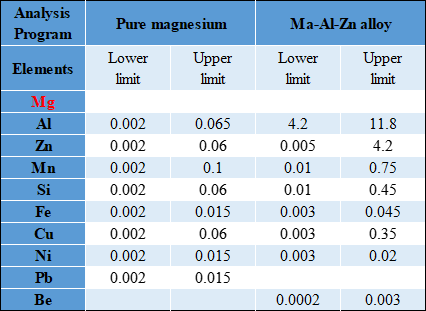

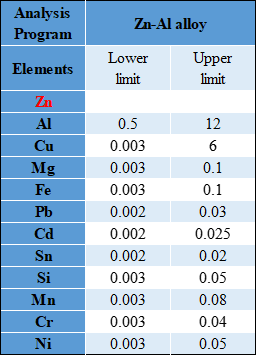

Analyze the matrix: iron, aluminum, copper, nickel, magnesium, zinc, titanium.

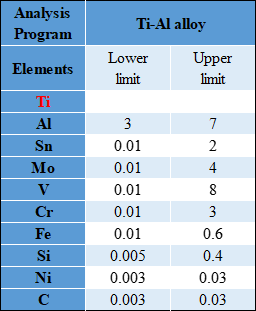

The analysis program is shown in the table below:

Technical parameters:

Optical system

High performance holographic diffraction grating with 2700 grating lines/mm, primary dispersion rate: 0.74nm/mm, secondary dispersion rate: 0.37nm/mm;

Focal length: 500 mm;

Spectral wavelength: 130-800 nm; The specific configuration range is selected by the actual customer application;

Single CCD 3648 pixels, with a maximum resolution of 16 * 3648 pixels;

All optical system automatic tracing;

A sealed vacuum chamber can avoid interference from dust and light;

Temperature stabilization system, constant temperature in the light chamber: 33 ℃± 0.1 ° C;

Using special materials to cope with drift;

Installing damping rubber pads in the light chamber to prevent vibration;

Direct optical path design, no need for fiber attenuation, good long-term stability of data, small curve drift, simple and easy to maintain design.

Spark table (excitation table)

An open spark excitation table that can analyze samples of various shapes weighing up to 20KG;

Argon gas blowing spark table, low argon gas consumption;

The static argon blowing design ensures that the heating time is less than 5 minutes;

Electrodes are easy to disassemble and maintain;

Convenient sample holder with safety protection, cannot be triggered due to abnormal placement;

Equipped with intelligent control inflation system: tidal flushing method, the cold engine (shut down for 12 hours) starts for no more than 30 minutes, the hot engine starts for about 5 minutes, and the ultra-low standby flow rate is less than 60ml/min;

Adapters for different samples can meet the needs of various samples (optional), and can analyze wires with different straight lines.

Spark power supply

The computer automatically controls the spark source and can set various parameters based on the test material;

Semiconductor controlled discharge excitation;

1 to 100 A plasma current;

Discharge parameters are password protected;

Adjustable excitation parameters;

A stable spark light source system is not affected by fluctuations in the power supply system;

The excitation parameters are calibrated and controlled by the excitation line and analysis program;

Analysis time: 15-30 seconds;

Two excitation frequency designs, high and low, with adjustable spark frequency of 20-1000Hz.

Control, electronic acquisition, and data readout systems

Spark duration adjustable from 10-10000us;

Microprocessor controlled multi-channel integration and data acquisition system;

High speed 16 bit analog-to-digital converter;

ISP mixed signal Flash microcontroller 100MHz;

High speed USB data transmission design;

Up to 16 high-performance CCD detection modules, customizable.

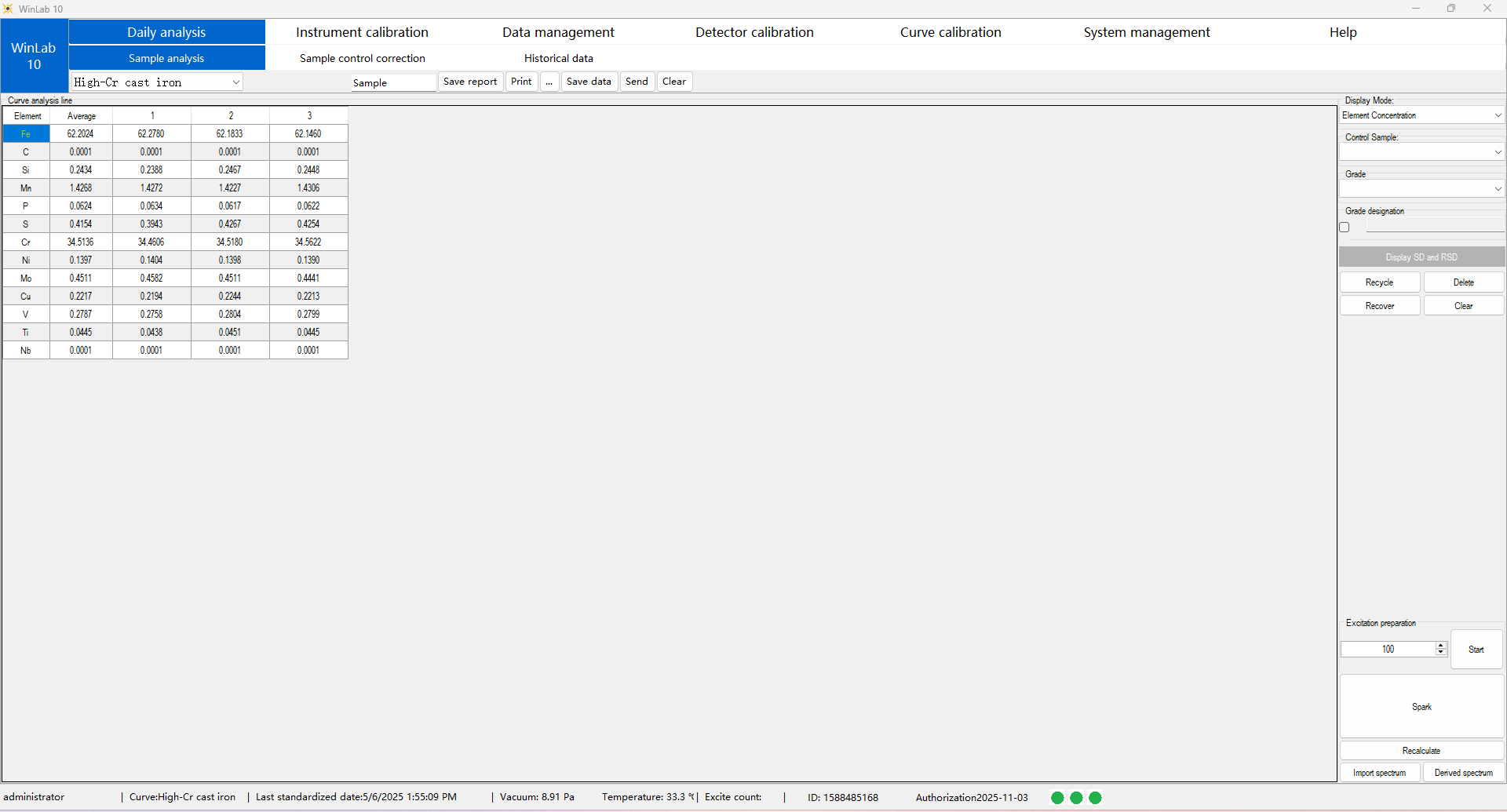

WinLab analysis software

Used under the Windows operating system;

Office operating habits software, user-friendly graphical interface;

Monitoring and controlling instrument status, self diagnostic function;

Process and calculate instrument data;

Simultaneously measuring each element and background;

Calculating the correction curve for each element requires consideration of various matrices (reference lines);

Spectral line database;

Reference Material Database;

Historical data database;

Graphics processing function, automatically calculating channel strength and deducting background strength;

Automatic optical path calibration function;

Create or modify analysis programs;

Curve calibration fitting;

Matrix correction;

Correcting interference between elements;

Standardization function;

Sample control correction function;

Measurement data processing function;

Statistical calculation function, calculating mean, standard deviation, and relative standard deviation;

Support the calculation of C equivalent or other parameters;

Analysis results of labeling beyond the calibration curve range;

Display test results and statistical values;

Edit sample information, print according to the editing template, or save to the historical database function;

Data transmission to external computers or central system functions;

Users can add curves of metal material grades for other alloy substrates as needed on site.

Source

220V+/-10%, single-phase, 50/60 Hz, 10 A, 1.0 KVA.

Laboratory environment

Temperature: 10-30 ℃

Relative humidity: 20-80%

Size

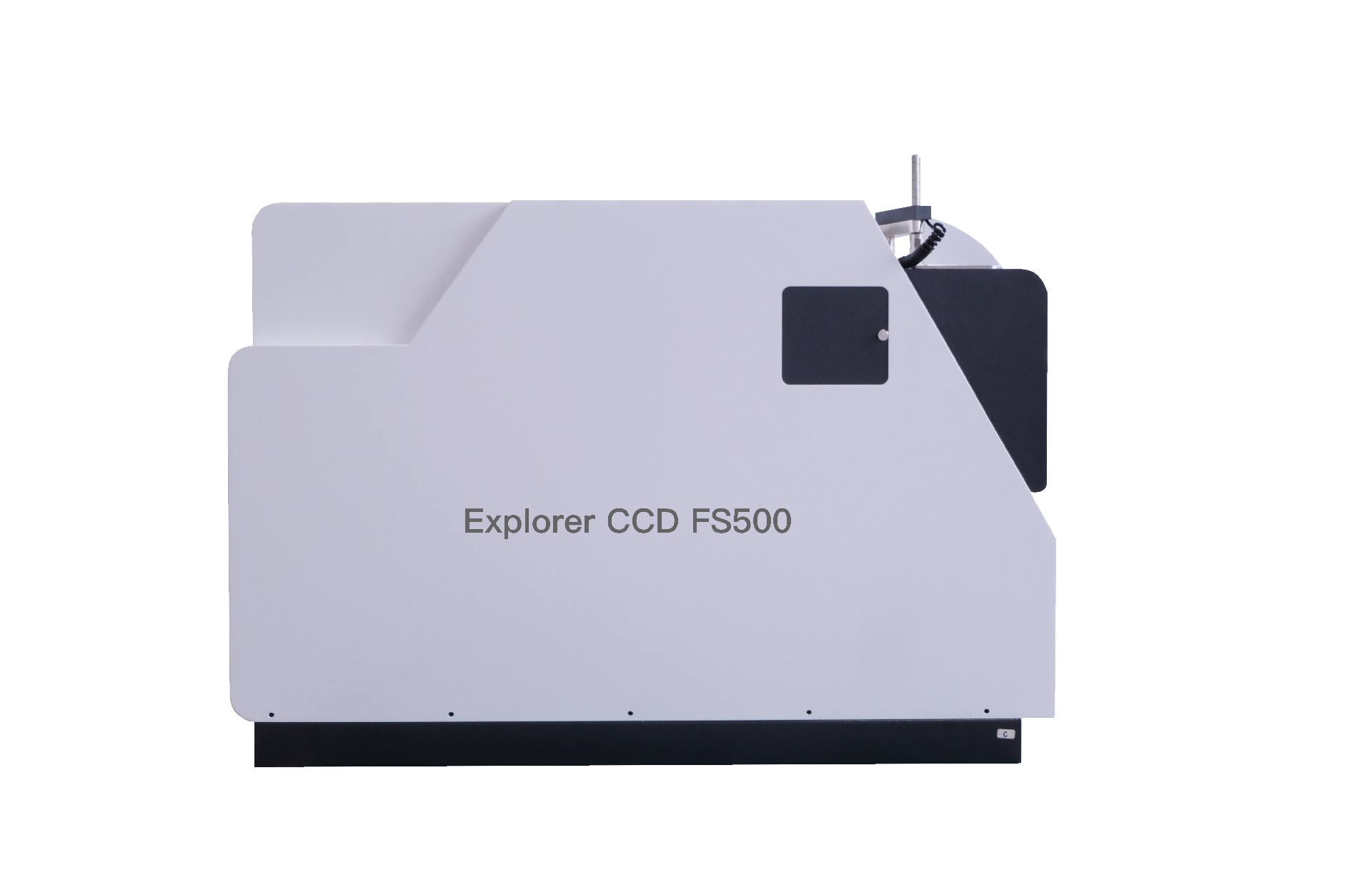

FS500 size: 930mm * 400mm * 630mm (length * width * height);

FS500 instrument weight: approximately 100kg.

Features and advantages:

Excellent and fast analytical performance;

Dynamic range: from ppm to%;

The open spark stage and special small sample fixtures ensure that the instrument is suitable for analyzing metal samples of various shapes;

Precision: better than 1% deviation;

Excellent nitrogen and oxygen element analysis performance;

High stability and reliability;

The detector system can be optionally equipped with up to 16 high-performance CCDs, increasing the flexibility of instrument matrix and element analysis upgrades;

High level standard calibration;

Variable Frequency High Energy Pre Spark (HEPS) Controlled by PC;

High precision temperature and pressure control;

Advanced software features, easy to operate, and easy to master;

Suitable for analysis of various metal materials.