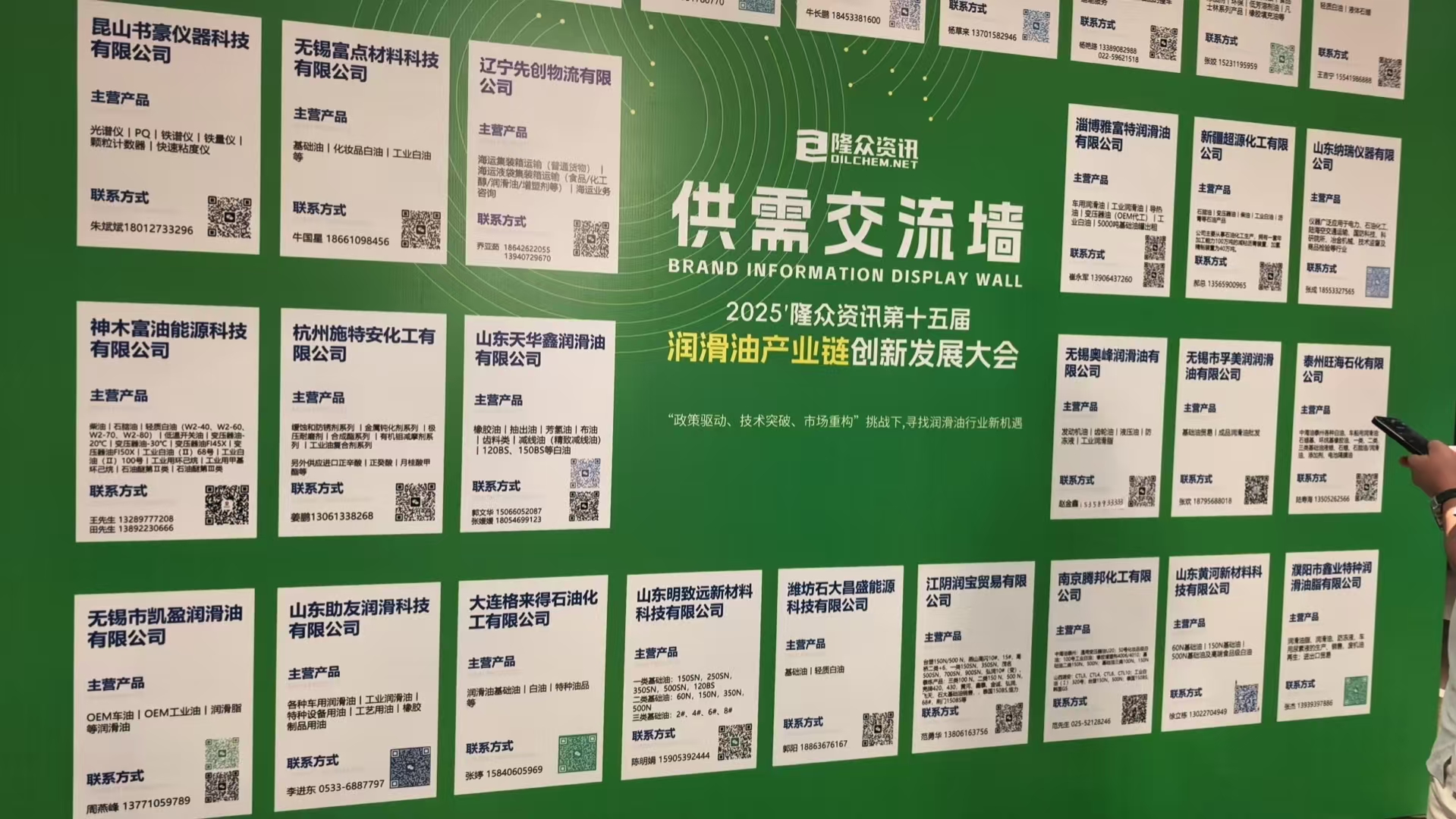

On September 4, 2025, Kunshan Soohow Instrument Technology Co., Ltd. made a brilliant appearance with multiple independently developed oil detection devices at the "2025 Lubricating Oil Industry Supply and Demand Exchange Conference" held in Wuxi, Jiangsu. This conference focused on core topics such as lubricant demand changes during the expansion period of new energy vehicles, technological upgrades under green low-carbon transformation, and deepening of domestic substitution, attracting hundreds of base oil producers, lubricant companies, end users, and third-party equipment manufacturers to participate.

As a national high-tech enterprise, Soohow Instrument showcased three star products at this conference, demonstrating its technological breakthroughs and industry empowerment capabilities in the field of oil analysis.

PO300 Petroleum Spectrometer: The "Fire Eye" for High-Precision Elemental Analysis

Based on the principle of atomic emission spectroscopy, the PO300 spectrometer, with its patented digital arc light source and high-resolution solid-state CCD sensor, can simultaneously detect 24 key elements (such as Al, Ca, Fe, etc.) in lubricating oil, with a detection range covering 0-6000ppm and a detection limit below 1ppm. Its built-in self-developed spectral analysis expert system supports data trend analysis and fault prediction, with a single test time of ≤30 seconds and a sampling volume of only 2mL, without the need for auxiliary reagents such as argon, making it suitable for various industries such as military, aviation, and electric power. This device precisely meets the needs of lubricant quality monitoring and equipment wear condition assessment, becoming the focus of attention at the conference.

PQ200-PQL Ferromagnetic Index Instrument: The "Intelligent Sentinel" for Wear Monitoring

In response to the demand for mechanical wear diagnosis, the PQ200 ferromagnetic index instrument adopts the principle of electromagnetic induction and can complete the rapid detection of ferromagnetic wear particles in lubricating oil in 7 seconds, with a measurement range of up to 0-15000PQ. The device is equipped with a patented sensor and an intelligent data management system, supporting automatic sampling and trend analysis, with a user-friendly interface that can intuitively reflect the degree of equipment wear, providing a scientific basis for lubricant pollution assessment and maintenance decisions.

SLPC300 Portable Particle Counter: The "Mobile Laboratory" for Cleanliness Assessment

The SLPC300 counter, based on the principle of light blockage, uses a high-precision laser sensor to achieve precise measurement of particle sizes in the range of 0.8-600μm, supporting 8+8 custom channel settings and multi-standard calibration. The device is equipped with a built-in lithium battery and corrosion-resistant piping, suitable for laboratory and field operations, and can determine the cleanliness level of samples in real time, helping users optimize oil replacement strategies and extend equipment life.

During the conference, the Soohow Instrument team engaged in in-depth exchanges with participants, discussing industry hotspots such as the development of special additives for new energy vehicles and the upgrading of high-end base oil testing standards. Company representatives stated that they will continue to drive the high-quality development of the lubricant industry through technological innovation, helping customers achieve green low-carbon transformation and intelligent management upgrades.

This participation not only showcased Soohow Instrument's technological accumulation and product matrix advantages in the field of oil detection but also, through actual cases and data, demonstrated its responsibility as an industry innovation leader. In the future, Soohow Instrument will continue to deepen industry-university-research collaboration, promote the improvement of testing standards and the process of domestic substitution, and contribute Chinese wisdom to the sustainable progress of the global lubricant industry.