The "2024 China International Lubricant Industry Conference - Focusing on Lubricants, Greases, Metal Processing&Industrial Cleaning, New Energy, Base Oil&Recycled Oil, and Smart Factory" hosted by Yimao Information Technology will be held in Shanghai from March 20 to 22, 2024.

More than 1000 industry guests from China, Russia, the Middle East, Europe, Indonesia, Singapore, Japan and other countries and regions, including lubricant and oil production enterprises, metal processing oil production enterprises, base oil production and trade enterprises, recycled oil production enterprises, additive enterprises, research institutes, instrument and equipment enterprises, technical service providers, and other supporting service providers, participated in the event. They established a learning and exchange platform for the domestic supply of lubricant industry raw materials and the export of additives and base oil resources, providing opportunities for the development of domestic and foreign trade in the industry.

Soohow Instrument cordially invites your joint participation~

Kunshan Soohow Instrument Technology Co., Ltd

Kunshan Soohow Instrument Technology Co., Ltd

Kunshan Soohow Instrument Technology Co., Ltd. is a national high-tech enterprise mainly engaged in the research and development, production, and sales of laboratory instruments, optical analysis instruments, and their software. Soohow Instrument was established in 2012. The Soohow Industrial Building covers an area of approximately 12300 square meters, with a research and development center of approximately 3000 square meters, an intelligent production workshop, and the establishment of the Suzhou Atomic Emission Spectrometer Engineering Technology Research Center. Since its establishment, Soohow Instrument has always adhered to technological innovation and has successively passed the Jiangsu Province Enterprise Credit Standard, Jiangsu Province Intellectual Property Standard, IS09001 Quality Management System Certification, ISO14001 Environmental Management System Certification, and has been honored as a "National High tech Enterprise" and "Kunshan Research and Development Institution". The company has authorized 57 intellectual property rights, including 9 invention patents.

The company will continue to adhere to independent innovation of high-end scientific analytical instruments, achieve overtaking in specific fields, and achieve milestone progress in replacing imported equipment.

Corporate Honors

|  |

|

|

|

|

|

|

Product Introduction

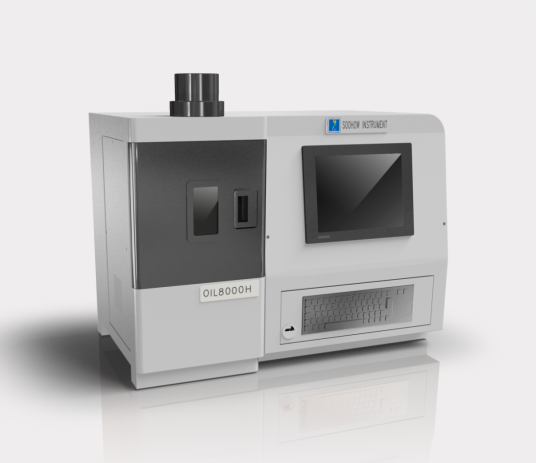

01. OIL8000H Oil Analysis Spectrometer

Product features

1. Applicable standards: ASTM D6595 (NB/SH/T0865-2013), ASTM D6728

2. Adopting a high-resolution solid-state CCD detector optical system, with a single pixel of 3648 bits and a pixel size of 8 * 200 μ m. Higher pixel, capable of detecting more effective spectral intensity

3. Built in industrial computer, the instrument has a small overall volume and is easy to transport

4. Short heating time, high reliability, suitable for naval environments

5. High detection accuracy and short single detection time

6. No gas or other chemical reagents are required to assist in excitation, and the oil sample does not require pre-treatment. It can be directly placed in a sample cup for testing

Application area

Any industry that uses lubricating oil and requires high precision, including military, various military units, aviation, railways, ocean going fleets, mines, refineries, power plants, oil recovery, manufacturing plants, commercial laboratories, racing teams, etc.

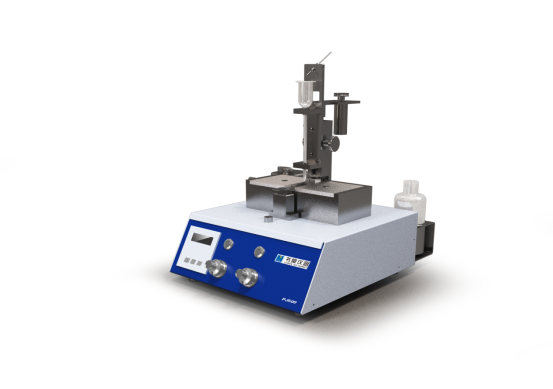

02. PA100 dual analysis ferrograph

Product features

1. Applicable standards: ASTM D7690, SH/T0573.

Once the oil sample is ready and inserted, the operation will automatically proceed and the operator can perform other tasks.

3. Convenient and intuitive button operation.

4. The sample flow rate can be adjusted and controlled to ensure consistent deposition and repeatability of the spectrum.

5. Produce two spectra simultaneously within less than 20 minutes.

6. Transparent spectra are convenient for detection and can distinguish between metal, organic matter, and non-metallic particles.

7. The particles are arranged according to their magnetization coefficient and size, which facilitates rapid analysis of the particles.

8. Rarely does particle accumulation occur, making it easy to observe particles that are important for reflecting the state of the machine.

9. The moisture in the oil has almost no effect on the production of the spectrum.

Application area

It can be widely used for ferrographic analysis and effective wear detection of lubricating oils in large machines and components such as internal combustion engines, gas turbines, gearboxes, bearings, hydraulic systems, etc. in various industries; In addition, it can also be used as a research tool in tribology and wear analysis for universities and research institutes.

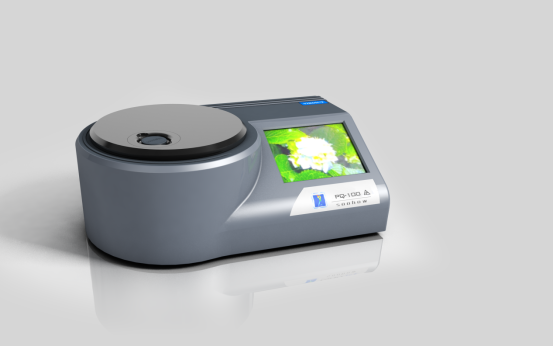

03. PQ100 ferromagnetic index meter

Product features

1. Applicable standard: ASTM D8184.

2. Adopting patented sensors and signal processing circuits, with good stability and high sensitivity.

3. Oil sample transmission and measurement are automatic, and one data can be measured in 7 seconds.

4. The oil sample does not require treatment and can be directly injected into an oil bottle for measurement.

5. Chinese and graphical interface, convenient for user operation and use. Users can input any number and letter to name the file.

Application area

It can analyze the content of iron abrasive particles in various samples of mineral oil, synthetic oil, hydraulic oil, gear oil, and lubricating grease in use.

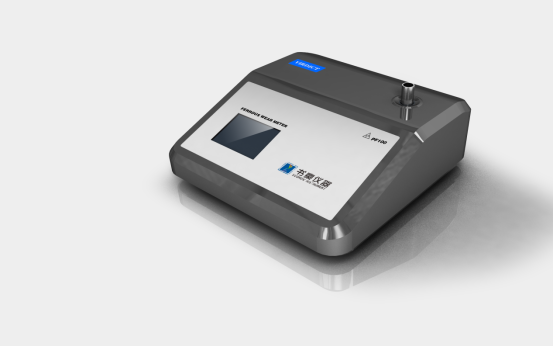

04. PF100 iron meter

Product features

1. Applicable standard: ASTM D8120

2. Mainly used to detect metal particles in oil samples extracted from cylinder friction oil

3. Simple graphical user interface

4. Quickly measure the ppm concentration value of ferromagnetic wear particles

5. Each sample has a testing time of less than 3 seconds

Application area

PF100 is widely used in wear monitoring of various machine systems and evaluation of lubricating oil products, and can also be used to study the friction state and wear mechanism.

05. PJ500 Thistle Tube Iron Spectrometer

Technical indicators

1. Particle inspection range of ferrography analyzer: 0-800 μ M;

2. Sample injection method: manually inject the sample into a capillary tube, which drips under gravity. The tested oil sample drips through its own gravity without passing through a peristaltic pump, avoiding the destructive effect of the peristaltic pump on the abrasive particles. The spectrum preparation process will not cause deformation of the abrasive particles;

3. Injection flow rate: 0.4ml/min;

4. Word analysis oil sample: 2-3ml;

5. Magnetic field: Maximum magnetic flux density ≈ 1.8T, maximum magnetic field gradient>0.5T/cm;

6. Magnetic field separation: Optimized permanent magnet design, high gradient magnetic field, ensuring neat arrangement of iron abrasive particles and avoiding stacking phenomenon;

7. Cleaning method: Automatic cleaning, can be scheduled;

8. Cleaning speed regulation: adjustable;

9. Spectral size: 60 × 24 × 0.17mm;

10. Display screen size: 3.5 "TFT;

11. Dimensions: length, width, height 340mm x 300mm x 430mm;

12. Weight: 9.6Kg

13. Working temperature: 18-35 ℃;

14. Power supply voltage VAC220 ± 10%, 50Hz.

Performance characteristics

1. Meet the ASTM D7690 ferrograph abrasive particle inspection standard and ASTM D7684 in use lubrication;

Standard for Microscopic Characteristics of Agent Particles and SH/T 0573-1993 Test Method for Wear Particles of Lubricating Oils in Service;

2. Efficient separation of abrasive particles and pollutant particles in oil samples;

3. The spectrum making process will not cause abrasive deformation;

4. High magnetic field gradient ensures the neat arrangement of iron abrasive particles and avoids stacking phenomenon;

5. Provide a reference graph library to accurately determine the location and cause of wear faults;

6. Less solvent required, no need for external compressed gas;

7. The design concept of cleaning agents evaporating into the air ensures the health of personnel;

8. One click rotary design, quick replacement of glass thistle tubes, easy to maintain, clean, and maintain;

9. The streamlined appearance design and exquisite combination structure make the overall design simple and elegant;

10. A brand new high-performance, low-power core with stronger resistance to electromagnetic interference;

11. The speed of spectrum making can be adjusted, which can effectively improve the success rate of spectrum making;

12. Instrument positioning device, which can adjust the distance between the oil pipeline and the ferrograph substrate to ensure the inlet of the oil sample

Maintaining consistency in the state improves the reproducibility of ferrography production;

13. Convenient to carry and can work in outdoor environments;

14. The ferrographic analysis method has a wide range of size inspection and can obtain various information about the abrasive particles;

15. Application scope: Used to separate and evaluate wear particles and pollutant particles in lubricating oil, hydraulic oil, coolant or fuel in use;

16. Testing content: concentration and size of abrasive particles; Morphology of abrasive particles (causes and mechanisms of abrasive particle formation); Composition of abrasive particles (the location where abrasive particles are produced).

06. IOA8000 Intelligent Oil Analyzer

Instrument Introduction

The intelligent oil analyzer is applied in the fields of rail transit such as railways and subways, as well as transportation equipment such as ships. It is widely used for the qualitative and quantitative analysis of worn metals, additive consumption, and pollutants in lubricating oils used in transmission and running parts. The uniqueness of this instrument lies in its superior analytical performance and simple operation, which can be operated by non professionals. Its important function is to be able to analyze the element content and the presence of wear elements and pollutants in lubricating grease within a few minutes, and the analysis work can be carried out in any place where oil is used. The intelligent oil analyzer is mainly used for analyzing sulfur elements, heavy metals, wear metals, elemental additives, pollutants, etc. in lubricating oil, grease, gasoline, jet fuel, kerosene, hydraulic oil, crude oil, residue, wax oil, alcohol gasoline, biodiesel, and other similar petroleum products.

Performance advantages

1. Using HAPG polarization target material effectively improves the sensitivity of light elements

2. Easy to operate, automatic sampling, one click completion of multiple sample testing, quick detection in one minute, making "oil change according to quality" possible

3. High resolution and good repeatability make "accurate measurement" possible; We have conducted centralized calibration and analysis on the concentration points of railway oil products in use and the special elements that railway oil products are concerned about, and implanted the data and curves into the equipment, making it more closely related to on-site application

4. Extremely cost-effective, analyzing multiple common elements makes "comprehensive analysis" possible

5. Lubricating grease is directly placed into the oil box for testing, without the need for heating, dissolving, and other steps on the grease, and without damaging the sample. The entire process is tested for no odor or harmful gases, and there is no need to place it in a fume hood, providing protection for the health of the test personnel

6. Equipped with a customized method package for analyzing railway lubricating grease elements, it can directly analyze the quantitative analysis of wear metals and additive elements in the grease. It can analyze multiple elements such as Fe, Cu, Si, Zn, Ca, S, Cl in gearbox oil, diesel engine oil, hydraulic oil, axle box bearing grease, traction motor grease, etc., achieving more targeted detection, making detection more convenient and data more accurate. 7. Low consumables cost and low consumption

Technical parameter

1. Analysis of element range: All elements between magnesium (Mg) and uranium (U)

2. Test objects: solid, powder, liquid

3. Content range: 2ppm-99.99%

4. Analysis method: Energy dispersive X-ray fluorescence analysis method

5. Detector: SDD/Fast SDD detector, with a minimum resolution of 130eV/125eV

6. Working temperature: -10 ° C~+50 ° C

7. Working humidity:<90%

8. Detection limit: The detection limit of S element in fuel is 10ppm/2ppm

9. Handling: One click testing, no need to select specific testing mode

10. Detection time: 30-300 seconds

11. Size: 400mm * 332mm * 272mm (length * width * height)

12. Weight: 4.6KG

Application area

1. Military field

2. Aerospace field

3. Power industry

4. Transportation industry

07. LPC100 oil particle counter (desktop)

Instrument Introduction

The LPC100 oil particle counter is an upgraded product based on LPC-L. This instrument is based on standards such as GB/T 18854-2002 (S01111-1999). Developed using the principle of light shading counting, it fully complies with the corresponding national military standards, national standards, and international standards. It can provide fast, accurate, reliable, and repeatable detection results as well as complete pollution monitoring and analysis reports, suitable for detecting particle contamination levels in hydraulic oil, lubricating oil, fire-resistant fuel oil, insulation oil, and turbine oil. It can be widely used in aviation, aerospace, power, petroleum, chemical, transportation, ports, metallurgy, machinery, automobile manufacturing and other fields.

Performance advantages

1. Adopting the counting principle of optical obstruction (shading) method developed by the International Hydraulic Standards Committee

2. High precision laser sensor with wide testing range, stable performance, low noise, and high resolution

3. Adopting high-pressure injection pump sampling method, the sampling volume can be set by oneself, the injection speed is stable, and the sampling accuracy is high

4. A positive and negative pressure combined injection system can achieve sample degassing, suitable for testing samples with different viscosities

5. Equipped with a built-in pressure sensor that can set pressure values and automatically determine the pressure inside the cabin to ensure safety

6. Built in air purification system to ensure testing is not contaminated

7. Built in multiple calibration curves, compatible with all commonly used domestic and international standards for calibration

8. Built in GJB-420A, GJB-420B, NAS1638, GB/T14039, 1S04406, SAE4059cpc, SAE4059F, SAE749D Г OCT17216, QC/T29104, JB/T9737, DLT432, HH005-2018 and more than ten commonly used standards can provide data results for all built-in standards in one test

9. Support custom standard testing for level determination

10. According to customer needs, up to 64 detection channels can be set up simultaneously

11. Built in data analysis system, which can provide all standard test data and pollution levels in one test

12. Can perform cleaning detection, pre-set target cleaning requirements particle concentration, display in real-time, and automatically stop when the requirements are met

13. Built in viscosity, moisture, and temperature sensor modules provide viscosity, moisture saturation, ppm values, and temperature reference values (optional) while accurately testing particle distribution

14. The particle size can be set arbitrarily, with nearly 10000 built-in particle sizes for easy particle size analysis

15. Multiple sampling containers such as standard sampling bottles or sampling cups can be used to meet the testing requirements of different industries

16. Fully functional automatic color touch screen operation, supporting both Chinese and English interfaces, simple and convenient operation

17. Can perform single channel and multi-channel calibration, achieving automatic calibration function

18. With RS232 interface, it can connect to computers or laboratory platforms for data processing. It has massive data storage and printing functions, can store 1000 sets of data, and supports USB storage of data

Technical parameter

1. Light source: Semiconductor laser

2. Particle size range: 0.8 μ M~600 μ M (according to 1-100) μ M or 4-70 μ M (c) calibration

3. Detection channel: 8-64 channels are optional, and the particle size can be set as much as possible

4. Sensitivity: 0.8 μ M (IS04402) or 3 μ M (c) (GB/T18854, ISO11171)

5. Resolution: ≤ 10% (GB/T18854, IS011171)

6. Repeatability: RSD<2%

7. Sample testing viscosity: ≤ 650cSt (if the viscosity is too high, it can be tested with heating or dilution methods)

8. Sampling volume: 0.2-1000mL, with an interval of 0.1mL

9. Sampling accuracy: better than ± 0.5%

10. Sampling speed: 5-80mL/min

11. Pressure chamber: achieving sample degassing and high viscosity sample detection

12. Maximum vacuum of the pressure chamber: -0.08Mpa

13. Maximum positive pressure in the pressure chamber: 0.8 Mpa

14. Maximum particle concentration: 12000~40000 particles/mL

15. Temperature (optional): 1-100 ° C; Acquisition accuracy: 1 ° C

16. Water activity (optional): 1-100% RH; Acquisition accuracy: 5% RH

17. Water content (optional): 1-300ppm; Collection accuracy: 1ppm

18. Power supply: 110-245V AC, 50HZ, 70W1

19. External dimensions: 40mm x 410mm x 650mm (length * width * height) Instrument net weight: 25kg

Application area

1. Military field

2. Aerospace field

3. Power industry

4. Transportation industry

08. Portable SLPC300 oil particle counter

Instrument Introduction

The SLPC 300 portable oil particle counter is an instrument suitable for both on-site detection and laboratory analysis. The instrument utilizes the principle of light resistance to measure the size and quantity of small particulate pollutants in oil media. By using precision plunger pumps and strictly controlling the sampling volume accuracy, offline or online testing of oil can be achieved. The calibration of the SLPC 300 oil particle counter follows two criteria, ISO 11171 and ISO 4402, and supports multiple detection standards including ISO 4406 and NAS1638. Users can also set their own detection standards. Eight detection channels provide users with a wide range of choices. The use of an oil particle counter is an effective analytical tool for detecting particle contamination in liquids.

Performance advantages

1. The counting principle of optical obstruction (shading) method developed by the International Hydraulic Standards Committee

2. High precision laser sensor with wide testing range, stable performance, low noise, and high resolution

3. Adopting high-pressure injection pump sampling method, the sampling volume can be set by oneself, the injection speed is stable, and the sampling accuracy is high

4. The pipeline is made of 316L and PTFE materials, which are corrosion-resistant and meet the testing requirements for various organic solvents and oil products

5. Used for laboratory or on-site measurement, optional pressure reducing device for online high-pressure measurement

6. External pressure can form positive/negative pressure, achieving the detection of high viscosity samples and sample degassing

7. Multiple sampling containers such as standard sampling bottles and sampling cups can be used, or directly connected to hydraulic systems for online testing to meet the testing requirements of different industries

8. Built in multiple calibration curves, compatible with all commonly used domestic and international standards for calibration

9. Built in multiple commonly used standards such as GJB-420A, GJB-420B, NAS1638, ISO4406, SAE4059E, and OCT17216. One test can provide data results for all built-in standards, support custom standard testing, and set the required standards according to customer needs

10. Can set up 1000 particle size channels for particle size analysis

11. Built in data analysis system, capable of automatically determining sample grade based on standards, with automatic data processing and printing functions

12. Color touch screen operation, Chinese and English input, with preset, input, modification, and storage functions, convenient and fast operation

13. The port has an RS232 interface, which can be connected to a computer or laboratory platform for data processing, or USB can be used for data storage

14. Built in lithium battery, suitable for outdoor operations, can be used without external power supply

15. Embedded design, high-strength shell, easy to carry, suitable for various types of construction machinery

Technical parameter

1. Light source: Semiconductor laser

2. Particle size range: 0.8 μ M~600 μ M (according to 1-100) μ M or 4-70 μ M (c) calibration

3. Sensitivity: 0.1 μ M

4. Custom detection channels: 8+8 channels, with arbitrary particle size settings

5. Sampling volume: 0.2~1000mL, with an interval of 0.1mL

6. Sampling accuracy: better than ± 1%

7. Sampling speed: 5-80mL/min

8. Cleaning speed: 5-80mL/min

9. Counting accuracy:<± 5%

10. Resolution: ≤ 10%

11. Repeatability: RSD<2%

12. Limit overlap error: 1200-40000 particles/ml

13. Offline viscosity detection: ≤ 100cSt (if the viscosity is too high, a pressure chamber can be optionally equipped)

14. Pressure range: Low pressure 0-0.6Mpa, high pressure up to 30Mpa (optional pressure reducing valve)

15. Online detection interval: Any setting

16. Test sample temperature: 0 ℃~80 ℃

17. Working temperature: -20 ℃~60 ℃

18. Storage temperature: -30 ℃~80 ℃

19. Power supply: AC100-240V, 50/60Hz

20. Battery capacity: 5200mAh

21. Battery running time: 6-8 hours

22. Boundary dimensions: 410mm x 320mm x 165mm (length * width * height)

23. Weight: 8.5kg

Application area

1. Military field

2. Aerospace field

3. Power industry

4. Transportation industry

Kunshan Soohow Instrument Technology Co., Ltd. invites you to gather at the Shanghai Lubrication Industry Conference from March 20 to 22, 2024 and visit the exhibition booth to discuss cooperation